SENSAP’s vertical solutions for the Printing and Carton-Converting industries focus on manufacturing execution monitoring and control, as well as materials flow traceability, encompassing all critical pre-press, press, post-press, and auxiliary operations (i.e. stock-control, warehouse management, production planning, workflow optimization, costing, and budgeting), which range from raw materials receiving to ready-products shipping.

SENSAP™ INTEGRA devices leverage world-class UHF RFID and BARCODE technologies combined with Vision Sensors and Optical Encoders to integrate seamlessly into the working environment of machine-operators. SENSAP™ INTEGRA devices interconnect to existing shop-floor industrial automation systems through PROFINET, AS, and TCP/IP interfaces. Equipped with SENSAP’s powerful autoTeach feature, INTEGRA automation modules comprise precise, reliable, and easy-to-use industrial control automation that requires minimum commissioning and setup time.

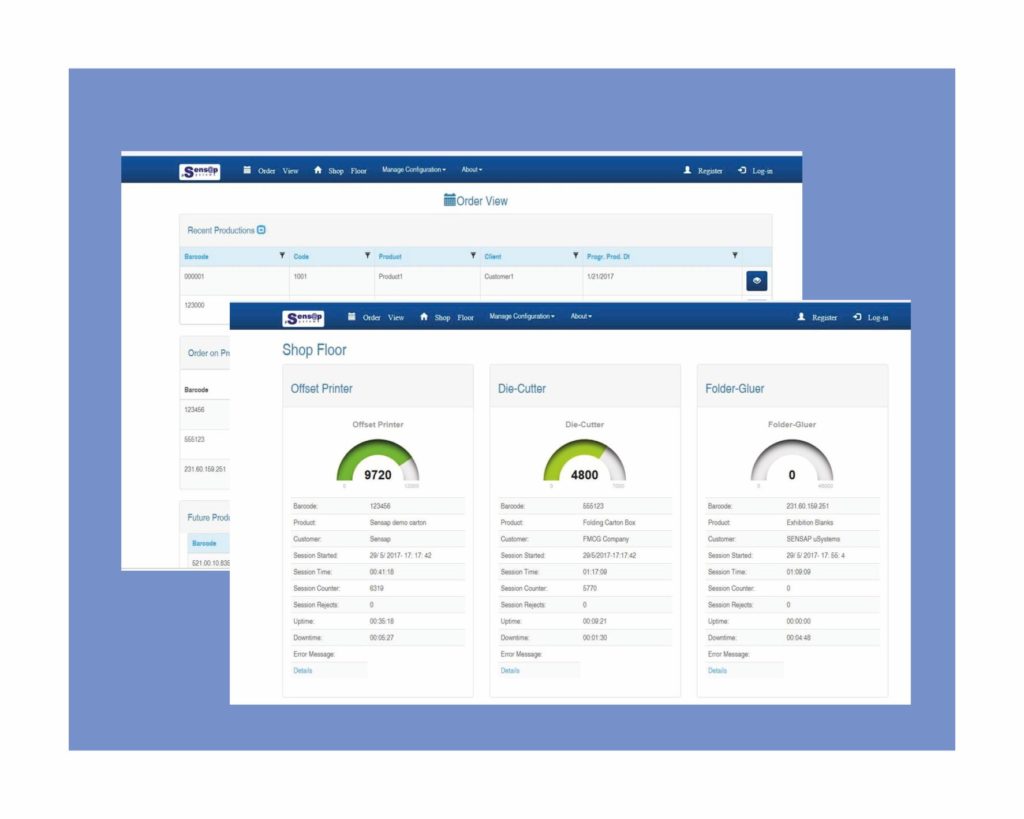

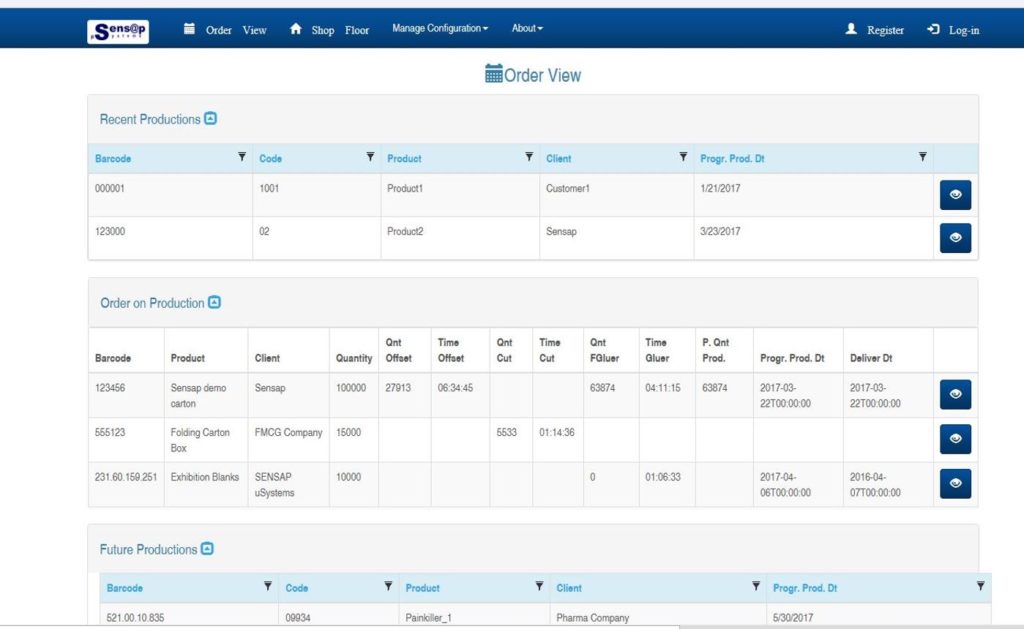

By means of SENSAP™ SBOX MIS server, INTEGRA hardware provides automatic and reliable synchronization of warehouse and shop-floor resources (i.e. raw materials, tools, equipment, and labor) with standing managerial data, while enabling remote visibility of operations performance through WEB-based dashboards. SENSAP’s innovative products allow for quick and easy installation onto almost any piece of Printing, Die-Cutting, and Gluing/Folding equipment, no matter its age or type, while requiring short training and roll-out times.

PRODUCTS